Whether in a plant or on an offshore platform, explosion proof actuators are the maestros of industrial automation. They are able to conduct a complex industrial orchestra with finesse and accuracy.

They are also capable of switching to a safe position in case of power failure. Learn more about our electric explosion proof actuators, UL HazLoc and ATEX certified.

Safety First

A simple way to make your actuator ATEX-compliant, this solution seals the circuit in an explosion proof housing that protects it from external explosive environments. This ensures that the flammable mixture does not reach the circuit and cause it to explode, protecting your equipment from ignition and ensuring safety.

Electric explosion-proof actuators like the ELZex and ELFZex series are designed to close quarter turn valves including ball valves, butterfly valves, plug valves and dampers. They meet UL HazLoc, ATEX and IECEx requirements.

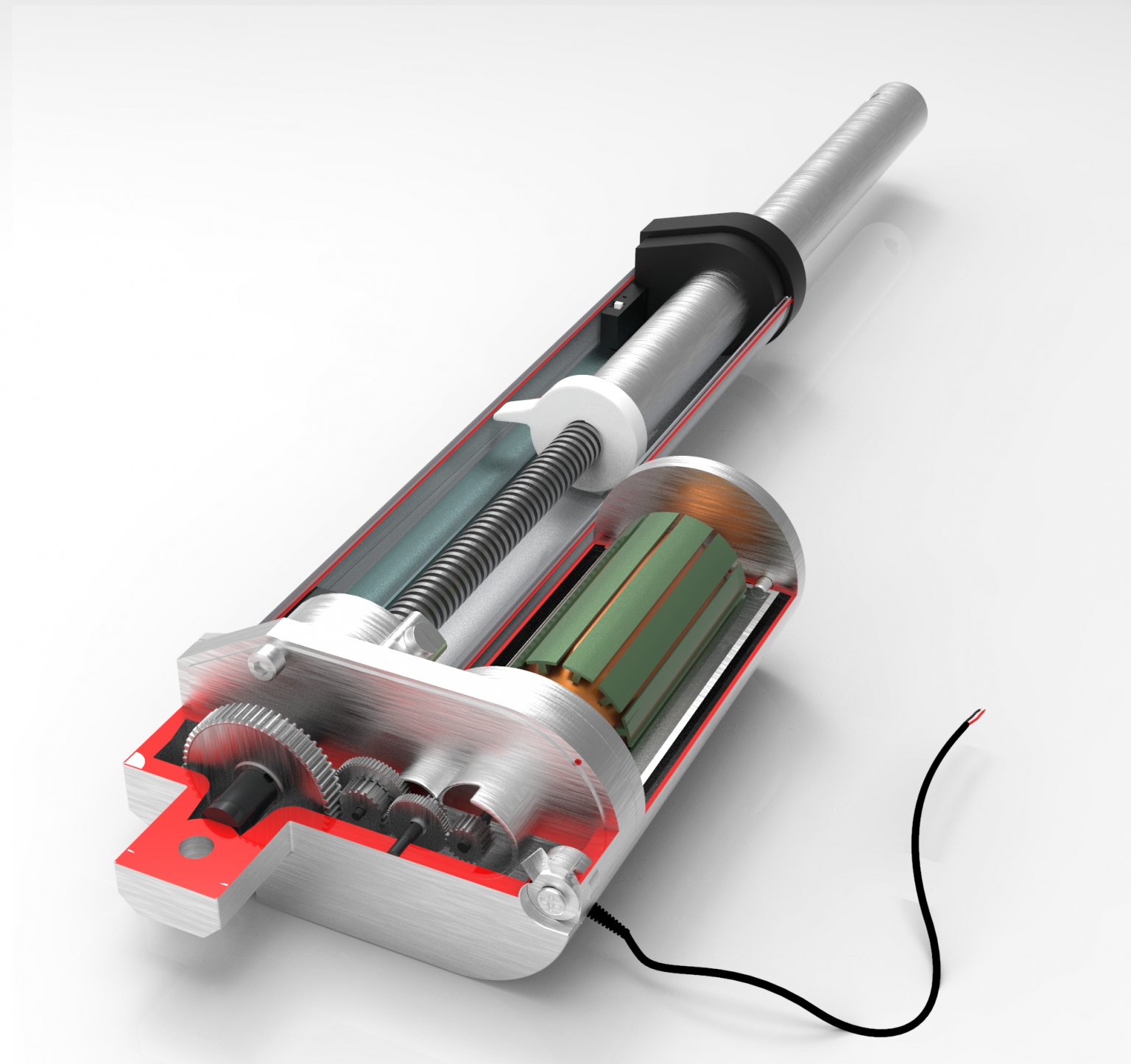

These are the straight shooters of the group, converting electrical energy into linear motion. The maestros of your industrial orchestra, these actuators are built to perform with precision and finesse. They also have incorporated fail-safe mechanisms that revert to a safe position in the event of an error.

Fault-Sensitive Circuitry

Fault-sensitive circuitry enables electrical equipment to detect faults within it without triggering an external explosion. This means your actuators will revert to a safe position even in the event of a power failure or other malfunction.

Linear actuators with ATEX approval are the straight shooters of the actuator world. These explode-proof actuators convert electrical energy into linear motion, allowing them to operate quarter turn valves, butterfly valves and dampers in hazardous environments.

Granaries, bakeries and breweries are another area where explosive-proof actuators are an absolute necessity. These industrial environments are often highly flammable and can produce static electricity, which can trigger an explosion. This is why ATEX linear actuators with a built-in spark arrestor are an ideal solution for these types of environments. They also allow you to connect directly between your controller and the actuator. This eliminates the need for an Ex-i module and intrinsically safe (IS) circuit wiring. This makes it faster, cheaper and simpler to get your industrial project up and running.

Incorporated Fail-Safe Features

Sun Yeh explosion-proof electric spring return fail-safe actuators are designed to rotate controlled devices (such as valves or dampers) into their fail-safe positions upon loss of power supply. A mechanical spring set is employed to provide the necessary position control.

Our explosion proof electric actuators can be used in any environment where the potential for flammable or explosive atmospheres exists. They are ideally suited for use in hazardous industries such as oil, gas, chemical and pharmaceutical production.

Our WE and XE series of explosion-proof electric actuators are specially designed for quarter-turn operating applications such as ball valves, butterfly valves, plug valves, and dampers. They are available in different ratings for Zone and Divisions based on your specific requirements. The WE and XE series are compact in size and ideal for small ball valves (2″ and smaller), dampers and other quarter-turn device automation usages. Our explosion-proof electric actuators are also CSA approved and ATEX certified to ensure your safety.

Tailor-Made Solutions

In a complex industrial landscape, optimizing efficiency and reliability becomes increasingly important. iVact electric actuators are built with these factors in mind, providing solutions that ensure the safety of your employees and equipment.

The straight shooters of the actuation world, they convert electrical energy into linear motion. They’re the James Bonds of the industry – cool under pressure and discreet. Incorporated fail-safe mechanisms revert the unit to a safe position in case of system malfunction. They’re like the maestros conducting a complex industrial orchestra.

These explosion-proof actuators have been designed for use in a range of hazardous environments and comply with the latest ATEX regulations (ATEX Zone 0, 1, 2, 21, and 22). They are also compatible with existing systems, tying directly into DCS systems using signals such as 4-20mA, FF, Profibus, or HART. They can also be equipped with various accessories, including rotary valve positioners and indicators. Contact us for more information or use our Design GUIDE PRO tool to determine the best product fit for your application.